Used Countercurrent Cooler for sale (1,280)

Hessen

Hessen Refrigerant charging station

AGRAMKOV SARATRONICRefrigerant filling system

Bayern

Bayern Vertical machining center

HwacheonVesta 1000

Germany

Germany CNC Turning- and Milling Center

BOLEYBE 42

+44 20 806 810 84

France

France DMG Mori Seiki NLX1500MC/500

DMG Mori SeikiNLX1500MC/500

Wadersloh

Wadersloh SHREDDER

HAMMEL750 E

Discover more used machines

Neuss

Neuss Ambulance

MAN Truck & BusIntensivtransportwagen

Untersteinach

Untersteinach Motor coach

NEOPLANStarliner/Travego/Tourismo/Top Zustand

Borken

Borken Ultra-low temperature thermostat 7.5 ... 12 liters

JulaboFP51-SL (v.2)

Neuss

Neuss Ambulance

Mercedes-BenzSprinter Rettungswagen

Österreich

Österreich Universal machining center

SHWUniSpeed 5-T

Neuss

Neuss Ambulance

Mercedes-BenzSprinter Rettungswagen

Neuss

Neuss Ambulance

Mercedes-BenzSprinter Rettungswagen

Neuss

Neuss Ambulance

Mercedes-BenzMC 519 CDI RTW Rettungswagen

Neuss

Neuss Ambulance

Mercedes-BenzSprinter RTW Rettungswagen

Lüneburg

Lüneburg CNC Turning and milling center

Nakamura-TomeNTJX

Lüneburg

Lüneburg Air conditioner / heater

HUBER & RANNERX-Case 08

Monheim am Rhein

Monheim am Rhein Machining Center - Vertical

AWEABM 1200

Kirchberg

Kirchberg Garbage truck

MANTGS 26.320 6x2-4 LL HS SL Speedline 27 PPK - ViS

Kirchberg

Kirchberg Garbage truck

MANTGS 26.320 6x2-4 LL HS SL Speedline

Wysoka

Wysoka Briquetting Press

COMAFERDINAMIC 250N 250kg/h

Germany

Germany POSmill H800U

POSmillH800U

Rende

Rende Roll-off tipper truck

DAFXF 480 6X2 Scarrabile Marrel 28ton.

Tatabánya

Tatabánya Chiller,heat exchanger, Baltimore Air

Baltimore AircoilBAC F100

Hadsten

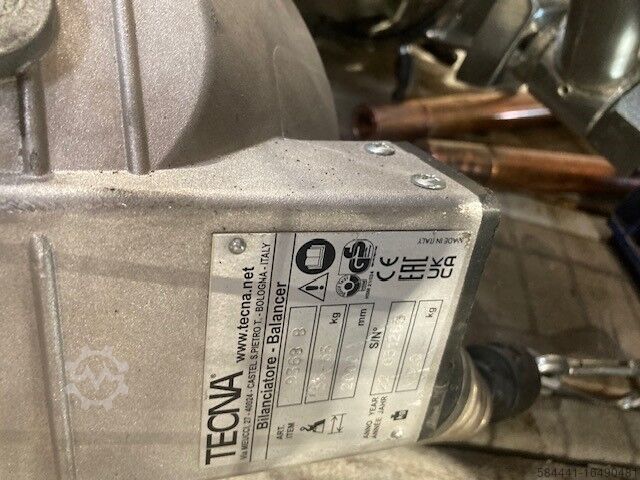

Hadsten Spot welding machine

Tecna3322/400/50

Petershagen

Petershagen Standard tractor unit

DAFXF 450 FT Hydraulik

Used Countercurrent Cooler (1,280)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84