Used Cnc Tube Bending Machine for sale (65,261)

Wiefelstede

Wiefelstede Reinforcing steel mesh bending machine 2.5 m

Maschinenfabrik BockU50-09 hydraulisch

Heilbronn

Heilbronn CNC Laser Cutting Machine

BystronicByAutonom 3015

Heilbronn

Heilbronn CNC Deep Hole Drilling Machine

AuerbachIA3 TLF-U

+44 20 806 810 84

Heilbronn

Heilbronn 3-Rolls Bending Machine

SchäferSRMVS 2000/20/15/11

Heilbronn

Heilbronn CNC Milling Machine

DMGDMU 60T

Discover more used machines

Korschenbroich

Korschenbroich CNC Gear Hobbing Machine Horizontal

Gleason-PfauterP210L

Düsseldorf

Düsseldorf CNC gear hobbing machine

PfauterPE150

Germany

Germany CNC portal plasma cutting machine

ESABSXE P1 4500

Nattheim

Nattheim CNC machining center

SCMRecord 110 S

Nattheim

Nattheim CNC machining center

SCMRecord 210 NT

Germany

Germany CNC Circular Grinding Machine

BahmüllerAS 650-CNC

Morbach

Morbach CNC milling machine

Deckel MahoDM 50

Italy

Italy CNC Machine Centres With Flat Tables

BIESSEROVER G 714

Zandhoven

Zandhoven CNC machining center

SCMTech Z2

Kraków

Kraków Cnc milling machine

XYZ Machine ToolsRMX3500

Częstochowa

Częstochowa CNC INFOTEC Machining center Model: 3121

CNC INFOTEC Machining centerModel: 3121

Częstochowa

Częstochowa CNC INFOTEC Machining center Model: 2515

CNC INFOTEC BearbeitungszentrumModell: 2515

Częstochowa

Częstochowa Tube end forming machine

ADDISONHG-70 RF DIGIPRO

Deinze

Deinze Vertical turning machines conventional & CNC

Mario CarnaghiTGF 5 1300 - Ø1400 mm CNC

Deinze

Deinze Universal Milling machines & CNC

Parpas OmvFAS - 4 P 5 axis Moldmaking CNC

Deinze

Deinze Universal Milling machines & CNC

Jarbe / AgursalX: 1500 - Y: 800 - Z: 500 mm

Deinze

Deinze Bed milling machine with moving column & CNC

CincinnatiX: 1800 - Y: 850 - Z: 800 mm CNC

Cesena

Cesena Round bending machines

MG3ROLL3000X50MM

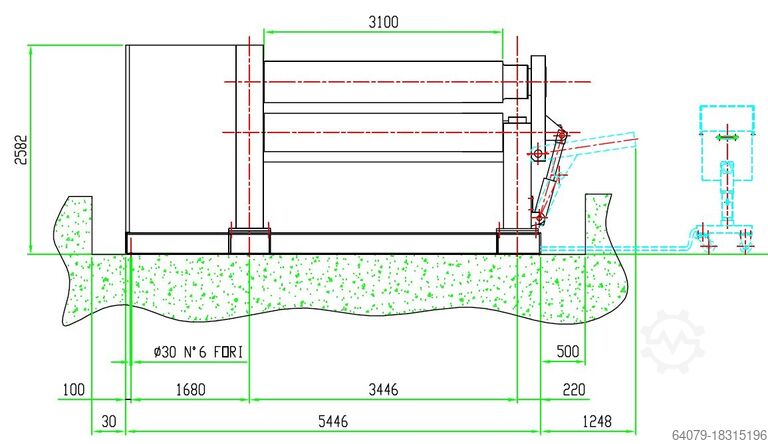

Austria

Austria Plate Bending Machine - 3 Rolls

HESSE by ISITANRM 1050 x 90

Wijchen

Wijchen CNC Horizontal Machine centers SCM Accord 25 FX 2018

SCMAccord 25 FX

Used Cnc Tube Bending Machine (65,261)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84