Emulsion care cart, emulsion filterBlotenberg

FA-300/U

Emulsion care cart, emulsion filter

Blotenberg

FA-300/U

fixed price plus VAT

€3,000

Year of construction

1995

Condition

Used

Location

Hövelhof

Show images

Show map

Machine data

- Machine type:

- Emulsion care cart, emulsion filter

- Manufacturer:

- Blotenberg

- Model:

- FA-300/U

- Machine number:

- 4141

- Year of construction:

- 1995

- Condition:

- used

Price & Location

fixed price plus VAT

€3,000

- Location:

- Mergelweg 206, 33161 Hövelhof, Deutschland

Call

Details about the offer

- Listing ID:

- A9592805

- Reference number:

- WT 114

- Update:

- 15.01.2025

Description

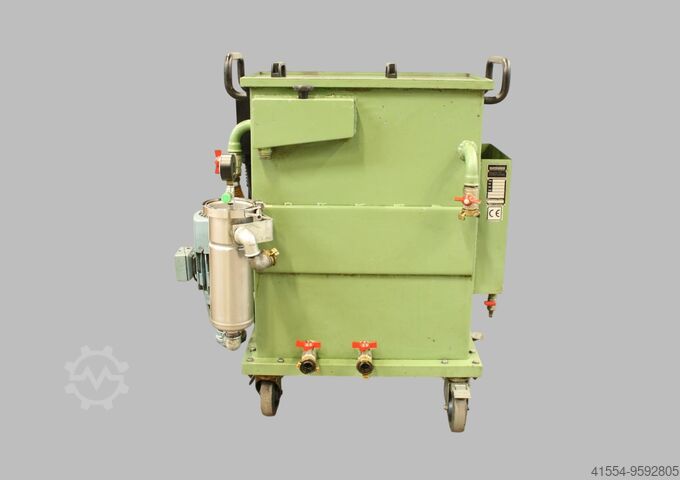

Emulsion maintenance trolley FA-300/U Blotenberg, filter unit

-WT 114-

Offered here is an emulsion care trolley/emulsion filter of the company Blotenberg.

Technical data:

Manufacturer: Blotenberg Saugsysteme

Blsdpfslf D Ugjx Aa Esd

Type: FA-300/U

Motor power: 0,25kW/ 220V / 3,1A

Year of manufacture: 1995

Flow rate: 300l/h

Serial number: 4141

dimensions: 1000 x 900 x 450mm

Suitable for:

Emulsion

Coolant

Cleaning solution

Wet cutting machine tools

Parts washers

Mode of operation according to the manufacturer:

The emulsion maintenance cart continuously draws in the contaminated emulsion mixture, separates the substances and returns the cleaned emulsion to the machine. All this is done purely physically - no spinning or centrifuging.

-WT 114-

Offered here is an emulsion care trolley/emulsion filter of the company Blotenberg.

Technical data:

Manufacturer: Blotenberg Saugsysteme

Blsdpfslf D Ugjx Aa Esd

Type: FA-300/U

Motor power: 0,25kW/ 220V / 3,1A

Year of manufacture: 1995

Flow rate: 300l/h

Serial number: 4141

dimensions: 1000 x 900 x 450mm

Suitable for:

Emulsion

Coolant

Cleaning solution

Wet cutting machine tools

Parts washers

Mode of operation according to the manufacturer:

The emulsion maintenance cart continuously draws in the contaminated emulsion mixture, separates the substances and returns the cleaned emulsion to the machine. All this is done purely physically - no spinning or centrifuging.

Seller

Note: Register for free or log in, to access all information.

Registered since: 2003

Send inquiry

Telephone & Fax

+49 5257 ... show

These listings may also fit your interest.

Listing

Ahaus

Ahaus

18,491 km

Drilling machines

AlzmetallAlzstar 40 SV

AlzmetallAlzstar 40 SV

Listing

Pirmasens

Pirmasens

18,678 km

Sheet metal folder, bending machine

Prod-Masz Abkantbank BiegemaschineAbkantbank ZGR 3140/1.0 3M

Prod-Masz Abkantbank BiegemaschineAbkantbank ZGR 3140/1.0 3M

Listing

Hagen

Hagen

18,528 km

Air filter electrostatic, air purifier

Indusa elstarEL 4001 NVAS R/O

Indusa elstarEL 4001 NVAS R/O

Listing

Neumarkt in der Oberpfalz

Neumarkt in der Oberpfalz

18,442 km

Vacuum packaging machine VC999

Inauen Maschinen AGVC999

Inauen Maschinen AGVC999

Listing

Neuburg an der Donau

Neuburg an der Donau

18,487 km

Sheet metal folder, bending machine

Prod-Masz Abkantbank 4m, BiegemaschineAbkantbank 4m/0.8mm = 4140mm

Prod-Masz Abkantbank 4m, BiegemaschineAbkantbank 4m/0.8mm = 4140mm

Listing

Pöttmes

Pöttmes

18,501 km

Cable stripping machine

GRS FeinwerkmechnikGRS 5

GRS FeinwerkmechnikGRS 5

Listing

Achern

Achern

18,690 km

Press aggregate for glues wooden trusses

SCHWÖRERHydraulisch

SCHWÖRERHydraulisch

Listing

Babenhausen

Babenhausen

18,550 km

Table dough sheeter 475 mm band width

RondoEconom 4000 STM 5304

RondoEconom 4000 STM 5304

Listing

Pöttmes

Pöttmes

18,501 km

Cable stripping machine

GRS FeinwerkmechanikGRS 9

GRS FeinwerkmechanikGRS 9

Listing

Germany

Germany

18,464 km

Rollfeeder cabinet

Keproma AGAlba, Indramat, Schleicher,

Keproma AGAlba, Indramat, Schleicher,

Your listing has been deleted successfully

An error has occurred