Used Ceiling Lights for sale (18,580)

Wiefelstede

Wiefelstede Ring light barrier

di-soricORSD 20 P2K-IBS

Wiefelstede

Wiefelstede Light barrier switching part

Leuze lumiflexULS-5

Wiefelstede

Wiefelstede Light barrier

VisoluxLS 500-DA-IBS/F2

+44 20 806 810 84

Wiefelstede

Wiefelstede Reflective light barrier

SickWL27-2F431S09

Wiefelstede

Wiefelstede Emergency exit sign light

HagenALUX Alz-31 Wand

Discover more used machines

Wiefelstede

Wiefelstede Machine recessed light

WaldmannEBLFE 136

Wiefelstede

Wiefelstede Cold light lamp

Classen+CoL 151

Wiefelstede

Wiefelstede Reflective light switch

ifmOF5027

Wiefelstede

Wiefelstede Telecentric lighting

Vision & ControlTZB60-B

Wiefelstede

Wiefelstede Light grid 2 pieces

TelcoR8-K32-46-A45-G71-S1-R

Wiefelstede

Wiefelstede One-way light barrier

LeuzeLSE 318K/P S12

Wiefelstede

Wiefelstede Machine light

WaldmannEBLCE 136

Wiefelstede

Wiefelstede Cold light lighting system

DedolightDedocool Cool Light Kit

Wiefelstede

Wiefelstede Reflective light barrier

LeuzeRT-318M/P-200-S12

Wiefelstede

Wiefelstede Emergency exit sign light

RZBGSUN 4

Wiefelstede

Wiefelstede Frequency-controlled conveyor belt + light barrier

MoscaGF 1000 x 500 mm

Wiefelstede

Wiefelstede System light

RittalSZ 2500.300

Wiefelstede

Wiefelstede Reflective light barrier

BannerQ85VR3DL-T9-B

Wiefelstede

Wiefelstede Reflective light switch

ifmOJ5122 OJB-FPKG/SO/AS

Wiefelstede

Wiefelstede Reflection light barrier

SickWT36-P410

Wiefelstede

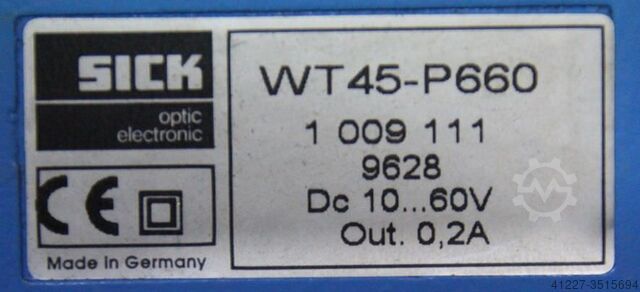

Wiefelstede Reflection light barrier

SickWT45-P660

Wiefelstede

Wiefelstede Light crane system 1000 kg

HelmSpannweite 3100 mm

Wiefelstede

Wiefelstede Light barrier switching part

Leuze lumiflexBasis-270

Wiefelstede

Wiefelstede Light barrier

VisoluxLS500-DA-IBS/F1

Wiefelstede

Wiefelstede Light barrier 1650 mm

SICKC4000

Used Ceiling Lights (18,580)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84