Er.-IS. Eroglu Industrie Service

Er.-IS. Eroglu Industrie Service from Schwerte

Wir sind ein International tätiges Maschinen- und Werkzeughandels Unternehmen und haben uns auf Werkzeugmaschinen spezialisiert.

Mr I. Eroglu

Hagener Straße 400

58239 Schwerte

Germany

Nordrhein-Westfalen

Current offers from similar dealers

Listing

Sankt Leon-Rot

Sankt Leon-Rot

18,615 km

Solvent parts cleaning system

Amsonic AGEGAclean 4100

Amsonic AGEGAclean 4100

Call

Condition: excellent (used), Year of construction: 2014, functionality: fully functional, For sale is a fully automatic hydrocarbon cleaning system Amsonic EGAclean 4100 in used, extremely well-maintained condition. The system is designed for reliable and reproducible parts cleaning (including ultrasonic, filtration, vapor phase, and vacuum drying) and is ideal for precision and series component cleaning.

1) Identification / Nameplate

Manufacturer: Amsonic AG (Precision Cleaning)

System type / model: EGAclean 4100

Equipment No.: 980 000 5161

Year of manufacture: 2007

CE marking: available

2) Process / Technology (EGAclean – Hydrocarbon)

Medium / Solvent class: A3 (hydrocarbon)

Solvent: ZESTRON VD

Typical process steps:

• Immersion cleaning in hot solvent (above flash point) with ultrasonic and microfiltration

• Vapor phase

• Vacuum drying

Practical advantage: consistent cleaning quality due to continuous distillation, highly compact design.

3) Technical Core Data (from nameplate)

Electrical connection: 400 V / 3/N + PE / 50 Hz

Power consumption: 32 kW

Current circulation: 47 A

Minimum fuse protection: 63 A

Heating power: 19.5 kW (28 A)

Max. bath temperature: 85 °C

Max. cleaning chamber temperature: 85 °C

Max. compressed air: 6…10 bar

Ultrasonic frequency: 20 kHz

Ultrasonic power: 1 × 1.0 kW

Destillation pressure: 60…100 mbar (abs)

Boiler pressure: 5 bar

Boiler temperature: 150 °C

Max. filling: approx. 426 l

Max. batch / basket weight: 50 kg

Flash point: min. 56 °C

4) Key Performance / Operating Data (from documentation)

Productivity: approx. 200–300 kg/h

Basket dimensions: 520 × 320 × 200 mm

Cleaning costs: 0.041 (unit according to template: “…/kg”)

Ncedpfx Aoycl Tmod Nol

Annual consumption: approx. 200 liters isoparaffin

Distillation residues are incinerated in cement plants

Air emissions: 1.7 kg VOC per year

Annual energy consumption: approx. 17,000 kWh

5) Operating Hours / Maintenance / Condition

Operating hours (readout): approx. 86,037 h (see photo, display with decimal point)

Condition: used, extremely well-maintained

Next maintenance: 2026

Listing

Rečica ob Savinji

Rečica ob Savinji

18,322 km

Heavy duty washing machine

ZippelD-93073

ZippelD-93073

Call

Year of construction: 1997, condition: reconditioned (used), functionality: limited functionality, machine/vehicle number: 500, Washing machine Zippel. In working condition, new pumps.

Nsdoycczhopfx Ad Necl

Listing

Linz-Land

Linz-Land

18,295 km

4-chamber ultrasonic cleaning system

KKSCL4-40-1111

KKSCL4-40-1111

Call

Year of construction: 2012, condition: used, functionality: fully functional, machine/vehicle number: 47412, KKS ultrasonic cleaning system with loading/unloading station for 3 baskets

Product baskets: 460x280x200(h) mm; basket load: max. 10 kg

4-chamber system, consisting of:

- Loading station for 3 baskets

- Tank 1: Ultrasonic cleaning (dual frequency 40/100 kHz)

- Tank 2: Immersion rinse

- Tank 3: DI water rinse

- Tank 4: Hot air drying

- Unloading station for 3 baskets

Including automatic goods transport (max. 15 kg)

Ncsdpfjyax N Aex Ad Nsl

Volume per tank: 145 liters

Oil separator mounted on tank 1 for bath conditioning

Plant dimensions: as per attached layout

Electrical connected load: 24 kW

System is operational and in good condition.

The equipment is sold without warranty/guarantee.

Operating manual is available.

Listing

Sanayi

Sanayi

16,589 km

Solar Panel Cleaning Brush

Mazaka Heavy IndustrySUNLITE SOLAR PANEL CLEANING BRUSH

Mazaka Heavy IndustrySUNLITE SOLAR PANEL CLEANING BRUSH

Call

Condition: new, functionality: fully functional, gearing type: hydrostat, color: green, overall weight: 1,200 kg, Year of construction: 2026, Equipment: additional headlights, adjustable boom, adjustable chassis, hydraulics, traction control, SUNLITE

SL240- SL340- SL440- SL510- SL640

Mazaka Sunlite solar panel cleaning brush is a professional cleaning solution designed to ensure photovoltaic modules operate at maximum performance.

Equipped with high-quality, non-abrasive soft bristles, it safely removes dust, dirt, bird droppings, and other environmental residues without damaging the panel surfaces. With its ergonomic design and durable construction, it delivers high efficiency even during long-term use.

Nedpfx Aox Thn Nod Nscl

Listing

Germany

Germany

18,608 km

Parts cleaning system PERO R1 / 414 EX_Year of manufacture 2017_Internal no. 231417

PeroR1 / 414 - Ex 7992

PeroR1 / 414 - Ex 7992

Call

Year of construction: 2017, condition: used, machine/vehicle number: IntNr231417, Technical Description – PERO RO

Manufacturer: PERO AG

Model: RO R1 / 414-EX

Year of manufacture: 2017 / 10

Machine type: Cleaning system / Degreasing unit

Process: Solvent cleaning (e.g. modified alcohols or hydrocarbons)

Technical data (typical for this series):

Cleaning system: Closed-loop, fully automatic

Working chamber dimensions: approx. 530 × 320 × 200 mm

Max. batch weight: approx. 50 – 80 kg

Solvent: Modified alcohol (hydrocarbon-based)

Ncsdpfsx Sv Uzjx Ad Nel

Drying: Vacuum drying

Control: PLC control with touch panel

Equipment: Integrated distillation unit, filtration system, oil separator

Power consumption: approx. 10 – 15 kW

Vacuum pump: Integrated

Condition: Very good, well-maintained condition – from ongoing production

Special features:

• Energy-efficient cleaning system with closed solvent circuit

• High cleaning quality with minimal solvent consumption

• Ideal for precision engineering and machining businesses

The machine can be inspected under power by prior appointment.

Subject to technical changes, errors, and prior sale.

Listing

Linz-Land

Linz-Land

18,295 km

Flood chamber compact cleaning system

MTMFKR 160 S

MTMFKR 160 S

Call

Year of construction: 1998, condition: used, functionality: unexamined, machine/vehicle number: 970323, MTM Flood Chamber Cleaning System

2-tank (washing and rinsing) unit including bath treatment via distillation unit

Batch size (incl. basket): 530x320x200h mm; Batch weight: max. 40 kg

Alkali tank: approx. 330L

Rinse tank: approx. 330L

Destimat (distiller): approx. 140L

System dimensions: 3,290 x 2,503 (with extension table) x 2,700(h) mm

Total connected load: 35 kVA, main fuse: 80A

A chiller is additionally included

Njdpfxjx Ncm Ee Ad Nocl

The system is sold in untested condition without warranty or guarantee.

Operating manual available.

Listing

Einbeck

Einbeck

18,369 km

Parts washer, cleaning system,

IBS Waschautomat Typ JUMBO 115-2Typ JUMBO 115-2

IBS Waschautomat Typ JUMBO 115-2Typ JUMBO 115-2

Call

Condition: good (used), Year of construction: 2015, functionality: fully functional, Available immediately!

Function

Easy operation thanks to a fully automatic cleaning process, allowing professionals to focus on other important tasks. The wash tank is filled with a mixture of water and water-soluble IBS special cleaner (washing solution). The contaminated items are placed in the rotating washing basket, and the lid is closed. After setting the desired washing temperature and time, the unit is switched on and the solution in the tank is heated. Inside the closed unit, the basket rotates at a constant speed around its own axis. The pump units draw the washing solution from the tank and distribute it through 6 stainless steel jet pipes with overlapping flat spray nozzles. The items are intensively sprayed from all sides with the hot solution due to the uniform rotation of the motor-driven basket.

Once the cleaning process is complete, the unit shuts off automatically.

Advantages

- 2 horizontally mounted pumps

- 6 three-dimensional stainless steel jet pipes

- Robust stainless steel construction

- Additional small parts cleaning basket made of stainless steel (Ø 170 mm)

- Rotating stainless steel wash basket, V-belt drive via separate motor

- Steam extraction

- Stainless steel sieve plate with filter basket above the wash tank

- Suction filter in front of the pump chamber

- Water shortage safety feature

Nedpfsx Izwmsx Ad Necl

- Individually height-adjustable feet

Technical Data

Capacity dipping tank / basket: 280 l

Diameter dipping tank / basket: 1150 mm

Load capacity: 350 kg / optional 500 kg

Temperature min. - max.: 0-60 °C

Working height: 700 mm

Dimensions (W x D x H): 1570 x 1510 / 1830 x 1495 / 2175 mm

Weight: 250 kg

Heating power: 10 kW

Spray amount: 2x10800 l/h

Pump pressure: 2.3 bar

Material: Stainless steel

Electrical connection: 13.5 kW / 400 V / 50 Hz / 32 A

Listing

Breitengüßbach

Breitengüßbach

18,437 km

Parts washer

TeijoC-1600-22SS-PD1

TeijoC-1600-22SS-PD1

Call

Year of construction: 2011, condition: excellent (used), functionality: fully functional, machine/vehicle number: 21224, 2-stage washing system with lifting door

Nsdsx Hplvjpfx Ad Njcl

Electrically heated, total approx. 50 kW

Loading capacity: 1,000 kg

Maximum part size: d=1,400 mm, h=800 mm

All parameters adjustable

Documentation and operating manual available

Listing

Borken

Borken

18,513 km

Cleaning system, parts cleaning machine

RosinkRFL 1650 Frontlader

RosinkRFL 1650 Frontlader

Call

Condition: excellent (used), Rosink RFL Front Loader

- Powerful water-based cleaning

- Modular system

- Cleaning of tall and long components

- Easy operation, compact design

- Low-maintenance operation

- Base unit in stainless steel

- Environmentally friendly

Ncodjx Exuqepfx Ad Nel

Concept

With the Rosink RFL front loader, we offer you an economical and user-friendly solution – especially suitable for cleaning tall components.

The proven Rosink cleaning technology and the highest quality are thus combined in one system.

The system is based on a single-bath system, standard with a rotary table, which can be expanded to a multi-bath system upon request.

Within the wash chamber, various programs can run depending on the configuration and requirements, such as washing, rinsing, drying, etc.

Features

Basic unit in stainless steel 1.4301

Tank with sloping bottom

Tanks and wash chamber including cladding and insulation

Rotary drive with 4-point bearing

Pneumatic lifting door with two-hand safety operation

Transport trolley or loading table with stainless steel 1.4301 drip tray

Pre-filtration via return filter baskets with usable height

Selectable filter element: 200 μm or 500 μm

Operating panel at the front with PLC for control (5 programs storable)

Flat jet nozzle system entirely in stainless steel 1.4301

Automatic refilling system with bath level control

Maintenance and inspection hatches for wash and rinse tanks

Technical Data

RFL 1650, variable depending on configuration

Width: 2900 mm

Height closed/open: 2800/4500 mm

Depth without/with transport trolley: 2650/4500 mm

Grid load capacity: 1000 kg

Grid dimensions: 1320 x 1320 mm

Grid diagonal: 1650 mm

Connection voltage: 400 V, 50 Hz, 3Ph/N/PE

Control voltage: 24 V / DC

Washing capacity: 750 l

Rinsing capacity: 500 l

Pump capacity (washing): 7.5 kW at 630 l/min at 4.5 bar

Pump capacity (rinsing): 4 kW at 250 l/min at 5.5 bar

Drying capacity: 12 kW

Heating capacity (cleaner): 36 kW

Heating capacity (rinsing): 27 kW

Weight: 3600 kg

Find more items – new and used – in our shop!

International shipping costs on request!

Listing

Frankenberg/Sa.

Frankenberg/Sa.

18,251 km

Parts cleaning device,

IBS Scherer GmbHF2

IBS Scherer GmbHF2

Call

Condition: good (used), Year of construction: 2003, Parts cleaning device, IBS, – used - :

Price per unit: €350 (net)

Manufacturer: IBS Scherer GmbH

Model: Type F2

Year of manufacture: 2003

Serial number: 44675

Power connection: 1/N/PE 230V, 50Hz

Rated power consumption: 18W, 0.2A

Load capacity: 60 kg

Width: 800 mm

Net weight: 50 kg

Drum size: 50-litre drum

Frame material: sheet steel

Height: 1125 mm

Cleaning medium: special cleaner

Ncjdpfxsx El A Uo Ad Nsl

Cleaning tank width: 790 mm

Cleaning tank depth: 540 mm

Condition: good

Available: immediately

Location: Warehouse Frankenberg / Saxony

Listing

Germany

Germany

18,384 km

Cleaning System

BvL OberflächentechnikRotocleaner 750

BvL OberflächentechnikRotocleaner 750

Call

Year of construction: 1996, condition: ready for operation (used), Offered is a cleaning and degreasing system with steam extraction fan and oil skimmer, year of construction 1996, basket: Ø720mm, internal height: 140mm, workpiece: maximum usable height: 450mm, maximum batch weight: 500kg, overhaul: 2011: completely overhauled, renewed: gear motor, heater, gas spring and heating elements, documentation: operating manual, technical documentation and CE declaration of conformity available, overall dimensions X/Y/Z: 1190mm/1170mm/1170mm, weight: approx. 290kg. Inspection: possible by appointment.

Nedpfxex Ect Io Ad Nocl

Listing

Linz-Land

Linz-Land

18,295 km

2-bath cleaning system & vacuum drying

AdunatecK100

AdunatecK100

Call

Year of construction: 2020, condition: good (used), machine/vehicle number: 054889, Aduna K100 2-Bath Cleaning System (Washing + Rinsing) incl. Vacuum Drying

Including the following equipment:

- Vacuum drying (Busch pump, rotary vane pump type RA)

- Pressure flood spray function incl. quick-flooding

- Spray function with 4-arm spray nozzles

- Reinforced pump system 5.5 bar

- Nozzle air purge to prevent cross-contamination of media

- Impulse drying with thermal coupling

- Chip filtration (bag filter) in media return

- Automatic sliding door (vertical with viewing window)

- Oil separator

- Swath steam condenser, air-cooled

- User-friendly, programmable control system

- Timer, media level control (level regulation)

- Automatic dosing unit

- Cascading from tank-2 to tank-2

- Remote maintenance

Automatic loading unit (buffer for 3 baskets in the loading area, 1 basket in front of the chamber, 3 baskets in the unloading area - 3-1-3)

8 Euro-standard baskets (dimensions: 670x480x400 mm)

Max. load: 100 kg

Ncedpsxz S Utjfx Ad Nel

Connected load: 27 kW, 55 A

For dimensions, see attached layout.

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

18,637 km

Parts cleaning system

PerkutePF 100

PerkutePF 100

Year of construction: 2005, condition: ready for operation (used), functionality: fully functional, empty load weight: 1,500 kg, workpiece weight (max.): 750 kg, machine/vehicle number: F101, TECHNICAL DETAILS

Pump output: 5.5 kW

Heating element output: 4.2 kW

Rotary basket load capacity: max. 750 kg

Ncsdpfxexztt De Ad Nel

Compressed air connection: max. 10 bar

MACHINE DETAILS

Unladen weight: approx. 1,500 kg

Electrical connection

Connection: 400 V

Current consumption: 63 A

Frequency: 50 Hz

Listing

Ettiswil

Ettiswil

18,779 km

Deionization plant

Call

Condition: excellent (used), VE-water circulation system for the treatment of rinsing baths

Nedpfx Adoxvllns Nocl

Listing

Ensisheim

Ensisheim

18,782 km

Cleaning washing defatting machine

PEROROBOMAT 7A

PEROROBOMAT 7A

Call

Condition: used, Cleaning washing defatting machine PERO type ROBOMAT 7A

Useful length: 1600 mm

Useful width: 1040 mm

Useful height: 960 mm

Loading height: 800 mm

Ncjdpfx Adjxr Eixs Nel

Maxi load weight: 1500 kg

Listing

Rahden

Rahden

18,386 km

Car wash

DÜRR ECOCLEANEcoCBase C2

DÜRR ECOCLEANEcoCBase C2

Call

Condition: used, Year of construction: 2010, functionality: fully functional, machine/vehicle number: 15129, total length: 280 mm, total width: 163 mm, total height: 240 mm, input frequency: 50 Hz, input current: 39 A, heating capacity: 10.25 kW (13.94 HP), space requirement length: 300 mm, space requirement width: 290 mm, Equipment: documentation/manual, This DÜRR ECOCLEAN "EcoCBase C2" is available for sale.

It is loaded via a small roller conveyor and Schäfer perforated crates. The roller conveyor is included.

Nsdpsxryzvofx Ad Nocl

Over 50 of these crates are also available (at an additional cost).

Additionally, there is a Euro pallet with various filters and oils for servicing.

Listing

Zielona Góra

Zielona Góra

18,047 km

Pressure washer

MarwisHydro Power 1200

MarwisHydro Power 1200

Call

Condition: new, functionality: fully functional, Hydro Power 1200 is a professional pressure washer, made from high-quality stainless steel and designed for a wide range of applications. This washer is ideal for turbocharger regeneration and the cleaning of heavily soiled components made of steel, cast iron, aluminum, and other alloys.

The cleaning process operates in a closed circuit, using MRS Cleaner Ultra Active washing fluid heated to 45 °C. The MRS Cleaner Ultra Active solution is delivered from a gun nozzle at up to 140 bar, ensuring thorough cleaning of hard-to-reach and heavily contaminated parts from carbon, grease, and oils. Both the temperature and the fluid itself enhance the washing efficiency. The washer is equipped with two filters and features adjustable leveling feet up to 20 cm. The washer lid is fitted with pneumatic struts for increased safety and work comfort. During cleaning, you can also use the installed flow-through brush or compressed air gun. The glass viewing window is equipped with cleaning nozzles to ensure clear visibility during operation.

Additional features:

- Thermally insulated tank – effectively protects the heated fluid from cooling too quickly.

- Glass cleaning nozzles

- Adjustable leveling feet

- Oil separator – extends the lifespan of the washing fluid

Optional accessories:

- Rigid lance

- Rotating table

Technical data:

Total width: 1,410 mm

Total depth: 800 mm

Min/max height (closed): 1,720/1,920 mm

Min/max height (open): 2,380/2,580 mm

Working width: 1,100 mm

Working depth: 700 mm

Working height: 620 mm

Weight: 200 kg

Working table load capacity: 200 kg

Working fluid capacity: 120–150 L

Temperature regulation: 0–45 ℃

Lance output: up to 12 l/min

Pressure: 140 bar

Ncedpfx Ajxnl Efjd Nol

Voltage: 3~400 V

Switch: foot-operated

WE ALSO OFFER OTHER HYDRO POWER PRESSURE WASHER MODELS IN SIZES 800, 1200, 1600, 2000.

PLEASE CONTACT US FOR A QUOTE ON OTHER MODELS.

Listing

Abu Dhabi

Abu Dhabi

14,273 km

Facade Cleaner

hyCleanerRED EVO 1

hyCleanerRED EVO 1

Call

Year of construction: 2023, operating hours: 4 h, condition: like new (used), functionality: fully functional, machine/vehicle number: 10220, The hyCLEANER® red EVO I cleans different forms of façades, surfaces and materials:

very gentle, effective, fast and above all, economic. The machine works with highpressure water and does not need any electrical connection. Both, the glass and the frames are cleaned simultaneously. All water leading elements are made out of stainless

Ncodpfoxnlz Hex Ad Nsl

steel. Purified-water can be used and the glass surfaces dry up, leaving no streaks behind.

A further advantage of hyCLEANER® red EVO I is the running wheels. They do not leave

any marks on the surface of the façade - gentle cleaning can be so easy!

Listing

Zielona Góra

Zielona Góra

18,047 km

Automatic basket washer

MarwisMRS Wash 1200

MarwisMRS Wash 1200

Call

Condition: new, functionality: fully functional, Basket Washing Machine MRS - WASH 1200

Application:

The device is designed for washing components of various sizes and weights. The washer is equipped with a mechanically driven rotary basket powered by a motor and spray nozzles.

Operating Description:

After switching on the main power, the bath heating process begins. Once the set temperature is reached, the washing cycle can be started. The primary washing phase is the first step, and its duration can be continuously adjusted using the timer located in the control box. When the set time elapses, the bath will end automatically.

STANDARD EQUIPMENT OF THE WASHER:

* Safety cover switch that disconnects during opening in the washing process

* Liquid level sensor in the tank preventing dry operation

* Temperature sensor

* Single spray arm

* Mechanically rotated basket

* Double filtration system

* Coarse mesh filter for insoluble contaminants (1mm mesh)

* Drain valve

Technical Data:

Basket diameter: 1200mm

Working height: 500mm

Basket capacity: 300kg

Working time programmability: 0-99 min

Washing temperature: 60°C

Heater power: 12kW

Tank capacity: 400l

Spray performance: 200l/min

Spray working pressure: 4.5bar

Overall width: 1750mm

Overall depth: 1750mm

Ncodpoxnlpdofx Ad Nol

Overall height (closed/open): 1250/2400 mm

Power supply: 3~400V

OUR OFFER INCLUDES OTHER MODELS OF AUTOMATIC BASKET WASHERS FROM THE MRS WASH SERIES WITH SIZES 800, 1000, 1200, 1500, AND EVEN 1500 XL.

PLEASE CONTACT US FOR OFFERS ON OTHER MODELS.

Listing

Zielona Góra

Zielona Góra

18,047 km

Automatic basket washer 2-in-1

MarwisHydro Wash 1200

MarwisHydro Wash 1200

Call

Condition: new, functionality: fully functional, warranty duration: 12 months, total width: 1,750 mm, total length: 1,750 mm, total height: 1,700 mm, type of input current: three-phase, The HYDRO WASH 1200 2-in-1 automatic basket washer is a multifunctional device, enabling fully automatic cleaning of parts in a motor-driven rotary basket. For parts with more complex shapes, high-pressure washing at 140 bar is available. Thanks to the combination of these processes, this machine is versatile and can be used in any workshop. It is particularly suited for companies specializing in turbocharger, steering gearbox, and transmission refurbishing, significantly streamlining workflow. To ensure user safety and stable washing parameters, an electronic control panel and a range of integrated sensors are employed.

Operating principle:

Before the first use, fill the tank with washing fluid. The recommended fluid is a solution of MRS Cleaner Strong concentrate and water in the specified ratio. The Hydro Wash offers both manual and automatic washing modes.

a) To activate automatic washing, prepare the device (fill with water and concentrate), close the metal glove cover, close the washer lid by simultaneously pressing two buttons (located at the front and rear of the device), and press the start button.

*Basket rotation possible when the lid is open by pressing the right pedal button or simultaneously pressing the two buttons at the front and rear. The condition is that the metal glove cover must be closed.*

b) To activate manual washing, close the washer lid by pressing the two buttons (front and rear) simultaneously. Open the metal glove cover and press the left pedal button.

STANDARD EQUIPMENT:

- Lid interlock sensor for safety when opened during washing

- Liquid level sensor to protect against dry operation

- Liquid temperature sensor

- Adjustable spray arms with nozzles made from stainless steel by Spraying System

- Mechanically driven rotary basket

- High-pressure pump (140 bar)

- Compressed air gun

- Pressure regulator with water separator

- Coarse mesh filter for insoluble contaminants (0.8 mm mesh size)

Nodpfjxm Ullox Ad Nscl

- Fine filter for contaminants

- Adjustable feet

- Drain valve

- Pneumatic cylinders

Technical Data:

- Basket diameter: 1200mm

- Working height: 500mm

- Basket load capacity: 300kg

- Programmable cycle time: 0–99 min

- Washing temperature: 60℃

- Heater power: 12kW

- Tank capacity: 400l

- Spray rate: 200l/min

- Working spray pressure: 4.5–6 bar

- Manual washing pressure: 140 bar

- Overall width: 1750mm

- Overall depth: 1750mm

- Overall height: 1700mm (2450mm with lid open)

- Power supply: 3~400V

Optional equipment:

- Belt oil skimmer

- Low-pressure lance kit

- Reinforced pump

OTHER DIMENSIONS OF HYDRO WASH 2-IN-1 WASHERS AVAILABLE!

MODELS 800 AND 1000 ALSO IN STOCK.

CONTACT US FOR DETAILS ON OTHER MODELS.

Listing

Zielona Góra

Zielona Góra

18,047 km

DPF filter cleaning machine

MarwisDPF DUO PREMIUM

MarwisDPF DUO PREMIUM

Call

Condition: new, functionality: fully functional, total length: 1,200 mm, total height: 2,100 mm, total width: 2,500 mm, empty load weight: 750 kg, input voltage: 400 V, water tank capacity: 400 l, warranty duration: 12 months, DPF DUO PREMIUM = CLEANING CABIN + DRYER FOR DPF/FAP FILTERS

This set of devices allows for maximum optimization of the regeneration process. A well-organized operator can work with three filters simultaneously.

Washes

Dries

Advantages of the DPF DUO Premium:

-> A separate dryer doubles work efficiency

-> We are the only ones to offer a large-diameter hose that connects to the DPF. A larger diameter = more water = more effective cleaning

-> Our filter mounting system is free of elements placed inside the DPF filter tube that could block the water flow. This allows the full performance of the water and air pump to be utilized, shortening regeneration time.

-> The large cabin provides the freedom to mount the cleaned filter. The operator, based on their experience, can choose the position in which the filter will be washed.

-> Protection against excessive pressure in the filter during cleaning

Ncsdpfx Aoxm Szqjd Nol

-> Protection against lack of airflow through the filter during drying

-> Possibility to individually set the cleaning program according to the filter capacity

-> Stable securing of the filter during drying

-> Three-stage dirty water filtration system

-> Water heating controller

-> Insulated water tank

-> Training at the customer's site can be provided

The device enables the removal of soot and ash from DPF/FAP filters without negatively impacting the filter structure, restoring up to 99% of the nominal flow rate. Our technicians have dedicated significant effort to ensure that both the cleaning procedures and the detergents used are safe for the environment and machine operators.

The operator checks the filter for mechanical damage using an endoscopic camera. If signs of melting, ceramic core cracks, or other apparent mechanical damage interfering with the DPF are detected, regeneration will not be possible. The regeneration process takes place in a closed chamber equipped with filters preventing harmful contaminants from escaping into the environment. Water with cleaning fluid circulates in a closed loop and is filtered throughout the process, significantly extending bath life. The DPF DUO Premium cleans filters using water, chemistry, and air. A precisely selected, computer-controlled sequence of water and detergent dosing, combined with air and impulses generated by compressed air, ensures high regeneration efficiency.

After the cleaning process is complete, an additional device dries the filter with air at 90°C, ensuring complete evaporation of the cleaning solution. After drying, the machine performs a final backpressure measurement. This measurement can also be taken before cleaning, allowing subsequent comparison of backpressure values before and after the process. The device is equipped with a printer that allows generating a measurement report.

The washing time for filters from passenger cars or light commercial vehicles is 20–40 minutes, which enables regeneration of up to a dozen filters in 8 hours. High efficiency combined with low operating costs guarantees a rapid return on investment.

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

18,599 km

Parts cleaning system

PERKUTESP 80

PERKUTESP 80

Year of construction: 2011, condition: ready for operation (used), functionality: fully functional, empty load weight: 320 kg, cage diameter: 790 mm, working height: 930 mm, machine/vehicle number: S2327, No reserve price – guaranteed sale to the highest bidder!

The payment deadline for the machine is 20/11/2025! Bidding obligates collection within the specified period from 01/12/2025 to 05/12/2025!

TECHNICAL DETAILS

Rotary basket load capacity: max. 500 kg

Compressed air connection: max. 6 bar

Loading height: approx. 930 mm

Usable basket diameter: approx. 790 mm

Fluid volume (wash solution): 140 l

Pump output (washing): 200 l/min

Spray pressure (washing pump): 3 bar

MACHINE DETAILS

Operating voltage: 400 V

Frequency: 50 Hz

Rated current: 15 A

Connection power: 1.5 kW

Dimensions & Weight

Dimensions (L x W x H): 1,300 x 1,300 x 1,500 mm

Ncsdpjxm Riysfx Ad Njl

Weight: 320 kg

Listing

Einbeck

Einbeck

18,369 km

Parts washer, cleaning system,

IBS Scherer GmbHTyp MINI 60 U

IBS Scherer GmbHTyp MINI 60 U

Call

Year of construction: 2025, condition: as good as new (ex-display), functionality: fully functional, Connection: 3.55 kW / 230 V / 50 Hz

External dimensions (WxDxH): 945 x 830 x 1025 mm

External dimensions (WxDxH, open): 945 x 830 x 1640 mm

Weight: 60 kg

Basket diameter: 600 mm

Useful height: 380 mm

Pump pressure: 2.2 bar

Spray volume: 4,200 l/h

Load capacity: 100 kg

The soiled item to be cleaned is placed in the rotating wash basket and the lid is closed. After setting the desired washing temperature and time, the unit is switched on and the cleaning solution in the tank is heated. Inside the closed machine, the basket rotates at a constant speed around its own axis. The pump system draws the cleaning solution from the wash tank and feeds it through 6 stainless steel spray pipes equipped with overlapping flat jet nozzles. The item is thoroughly sprayed from all sides with hot solution during even rotation of the basket, which is driven by the jet action.

Ncjdpsxiwc Sjfx Ad Nol

After the cleaning cycle is complete, the unit shuts off automatically.

Advantages:

- 1 horizontally mounted pump

- Flow rate: 70 L/min

- 3 three-dimensional stainless steel spray pipes

- Robust stainless steel construction

- Additional small parts cleaning basket made of stainless steel (Ø 170 mm)

- Rotating stainless steel wash basket driven by water jet

- Steam extraction

- Stainless steel perforated plate with filter inlets above the wash tank

- Water shortage safety device

Listing

Wald

Wald

18,661 km

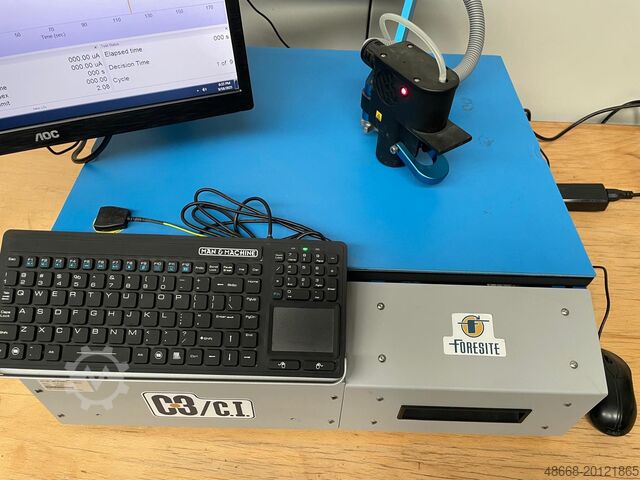

Critical Cleanliness Control Tester

ForesiteC3 / C.I.

ForesiteC3 / C.I.

Call

Condition: ready for operation (used), Foresite C3 / C.I. Critical Cleanliness Control Tester Analytics Technology

Year of manufacture: 2011

The C3 is unique among electronics cleanliness quality testers. It remains the only tester on the market that indicates whether a specific, critical area of a PCBA (Printed Circuit Board Assembly) is clean.

Simply select the components and/or circuit areas most sensitive and vulnerable to contamination and/or reliability issues, and test a small area (0.1 in²). The C3 quickly provides feedback as to whether potentially detrimental residues, often caused by manufacturing processes, are present.

Once the critical areas to be tested have been identified, the operator simply inserts a new disposable test cell into the vapor head and manually positions the head via the articulated arm over the test area. The weight of the arm and vapor head seals the test cell on the test surface. The operator then starts the automated testing sequence. Within 7-10 minutes, the operator knows whether the tested product area meets cleanliness standards. The C3 can be used directly in the production area.

At the end of the test, the cell can be easily removed using the cell ejector on the head. The test sample in the cell, efficiently extracted from the small test area using steam, can undergo further analysis to identify specific contaminants and their concentrations. The entire test is simple and straightforward for the operator, with results not dependent on operator skill. The use of Pro-Site single-use test cells and extraction solution prevents cross-contamination of samples.

You are welcome to arrange an inspection.

We can also organize cost-effective shipping for you!

You will receive a proper invoice.

For foreign customers, a net invoice can also be provided, provided a valid VAT ID number is available.

Njdpfxsxhckls Ad Nscl

Subject to prior sale.

Visit our shop and take a look at our other offerings as well.

Brand names and trademarks mentioned are the property of their respective owners and are used solely for identification and product description purposes.

Technical data deviations and errors in the description of the item may occur and are subject to change.

Listing

Germany

Germany

18,384 km

Continuous cleaning system made of stainless steel

BVL OberflächentechnikDAD-2BL

BVL OberflächentechnikDAD-2BL

Call

Year of construction: 2014, condition: excellent (used), functionality: fully functional, BVL Oberflächentechnik DAD 2BL (YUKON) Year of manufacture: 2014

For consistently clean components in continuous operation

Continuous flow cleaning system made of stainless steel with oil separator for uninterrupted material throughput. The parts to be cleaned pass continuously—or, if needed, in cycles—through successive treatment zones. Cleaning is carried out by passing the parts by fixed nozzle systems.

Designed for components with dimensions approx. 400 x 100 x 200 mm

Wire link conveyor transports the components lying flat or standing upright through the cleaning system

• Surrounding nozzle frame – the offset nozzle arrangement enables all-round cleaning

• Separation of treatment zones reduces cross-contamination

• Nozzle and frame adjustment to suit component

• Customizable useful dimensions, load capacity, and pump output

Process steps occur in successive treatment zones:

• Spray cleaning – series connection of various wet treatment zones (washing, degreasing, phosphating, rinsing, passivation)

• Drying

Tank capacities:

Washing tank: 800 liters

Rinsing tank: 500 liters

Heating capacity:

Washing tank: 48.0 kW

Rinsing tank: 30.0 kW

Washing tank pumps: 3.0 kW

Rinsing tank pumps: 2.2 kW

Washing pump pressure: 3 bar

Rinsing pump pressure: 2 bar

Drying fan: 2.2 kW

Drying heater: 18 kW

Operating temperature: min. 45°C to max. 60°C

Each machine includes stainless steel drip trays for leakage protection—these are included in the price and will be delivered with the machines.

Ncedpfjxcun Eex Ad Nol

WE HAVE 2 IDENTICAL MACHINES AVAILABLE