Water, Oil, Soap, AdBlue filling machinePROTON EE-ELEKTRONIKA d.o.o

XFR1000

Water, Oil, Soap, AdBlue filling machine

PROTON EE-ELEKTRONIKA d.o.o

XFR1000

Year of construction

2025

Condition

New

Location

Šašinovec

Show images

Show map

Machine data

- Machine type:

- Water, Oil, Soap, AdBlue filling machine

- Manufacturer:

- PROTON EE-ELEKTRONIKA d.o.o

- Model:

- XFR1000

- Year of construction:

- 2025

- Condition:

- new

- Functionality:

- fully functional

Price & Location

- Location:

- Krcevina 4, 10360 Soblinec, Hrvatska

Call

Technical details

- Total width:

- 2,400 mm

- Total length:

- 15,000 mm

- Total height:

- 2,800 mm

- Pressure:

- 8 bar

- Power:

- 10.9 kW (14.82 HP)

- Empty load weight:

- 6,400 kg

- Input voltage:

- 400 V

- Filling weight (min.):

- 200 g

- Filling weight (max.):

- 5,000 g

Details about the offer

- Listing ID:

- A17231422

- Update:

- 25.09.2025

Description

XFR 1000

Liquid Media Filling Line

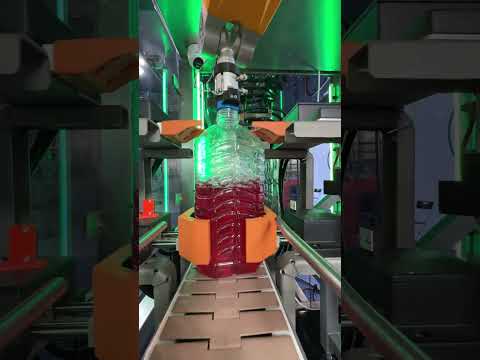

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

Fsdpfx Afjuq Nv Tjneft

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Liquid Media Filling Line

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

Fsdpfx Afjuq Nv Tjneft

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Documents

Seller

Note: Register for free or log in, to access all information.

Send inquiry

Telephone & Fax

+385 43 3... show

These listings may also fit your interest.

Listing

Niedźwiedź

Niedźwiedź

17,853 km

Bitzer Compressors unit with condenser

BITZERHSK7471-90-40P

BITZERHSK7471-90-40P

Listing

Austria

Austria

18,332 km

Pasteurisationplant with Baginbox filler

Kreuzmayr MaschinenbauPAS600+KBF

Kreuzmayr MaschinenbauPAS600+KBF

Listing

Baraginė

Baraginė

17,441 km

Pallet production machine

STAKMAPALLETSTAR

STAKMAPALLETSTAR

Listing

Strenči

Strenči

17,170 km

Complete sawmill (stationary)

Soderhamn/AriVislanda/Valon KoneSawmill

Soderhamn/AriVislanda/Valon KoneSawmill

Listing

Skarżysko-Kamienna

Skarżysko-Kamienna

17,745 km

Demineralized water station

ROMERRDI-2 / RDI-4

ROMERRDI-2 / RDI-4

Listing

Nijverdal

Nijverdal

18,488 km

Kemper ST75 A

KemperSt75 A

KemperSt75 A

Listing

Italia

Italia

18,559 km

Beverage making machine

Canning KHS Line Bottling 25.000 cphCans Complete Canning KHS 2017

Canning KHS Line Bottling 25.000 cphCans Complete Canning KHS 2017

Listing

Lēdmane

Lēdmane

17,249 km

Concrete block - manufacturing plant

LM and Metalika

LM and Metalika

Listing

Schorfheide

Schorfheide

18,095 km

Stationary mixing plant

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

Listing

Tata

Tata

18,035 km

Eccentric press 250ton

AIDA NC1-250250ton

AIDA NC1-250250ton

Your listing has been deleted successfully

An error has occurred